Design Process Simplified

The design process can be streamlined and bring physical models into reality in a fraction of the time traditional methods take by rapid prototyping. For example, where a process might have previously required a few months, it can now be done in a few days or hours. Since rapid prototyping eliminates the time-consuming processes of creating molds and establishing production lines, this quick turnaround is possible. You are no longer required to cut out the model by hand, instead you can simply take a 3D model meant for 3D printing, or SLA, SLS arms. In a study from last year, firms that adopted rapid prototyping reduced their product development cycles by 63 percent.

Enabling Iterative Testing

Rapid prototyping means that they can be testing iteratively. This enables product teams to iterate design multiple times with minimal latency. Every prototype yields critical feedback for an immediate feedback loop that can be applied to the current work, avoiding large-scale, expensive changes post-production. This means that businesses that reap the benefits of rapid prototyping develop multiple design alternatives in the time that it takes to hard tool one prototype, giving them approximately a 50% time-to-market advantage.

Cost Reduction in Innovation

Rapid prototyping also reduces development cost significantly. With fast prototyping, businesses can avoid the high costs implicated with traditional prototyping methods like injection molding that frequently demand expensive tooling and set up because the technology makes it easy to produce prototypes. This creates an opportunity for startups and small businesses to innovate without the heavy capital expenditure of the past. According to reports, the use of rapid prototyping technologies can reduce the cost of prototyping by 70%.

Providing Specialised Solutions

The rapid prototyping difference is really that they are providing a solution that is highly customized and quick. Especially in the field of healthcare, this is crucial since we need exactly tailored medical products based on the patient e.g. prosthetics. Since customization costs or takes time with rapid prototyping it means there can be an opportunity for mass personalization. Data from health care revealed that using rapid prototypes made it possible to 40% more in the production of individualized implants and other devices compared to way of doing 5 years ago.

Foster Collaboration and Creativity

Collaborative: This where rapid prototyping scores big as it allows teams to work together on physical models, rather than relying on renders and more traditional forms of prototyping. This type of hands-on interaction leads to faster communication and ideation cycles, which are essential for innovation. Rapid prototyping, which allows physical tests of ideas to be made faster than ever before, now makes creative, experimental projects more possible, significantly expanding the realm of the possible in product development.

Use Cases & Industry Applications

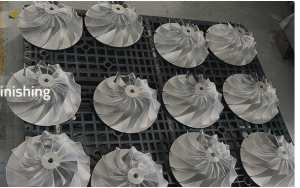

Rapid prototyping have become increasingly common in emerging fields of innovation in aerospace, automotive, consumer electronics or even construction, they enable companies to work on more complex solutions, and support more creativity. For instance, in the aerospace industry, rapid prototyping is used to test parts and components in different conditions before being manufactured to avoid potential risks of new aerospace designs.

The Future of Innovation : Visualized

Opting for rapid prototyping is not simply an exercise in speeding up production, but one that reimagines the entire product development and innovation process. Rapid prototyping extends a company with the speed, flexibility, and cost advantages of producing prototypes faster than before, giving companies the ability to bring new, innovative products to market far faster than ever before. See how Rapid Prototyping can change the course of your project schedule and design options.